Introduction

Wood wool wall panel is made of dried wood after planing into wood silk. Then put it into the chemical liquid immersion, and then add cement slurry pressed into board.

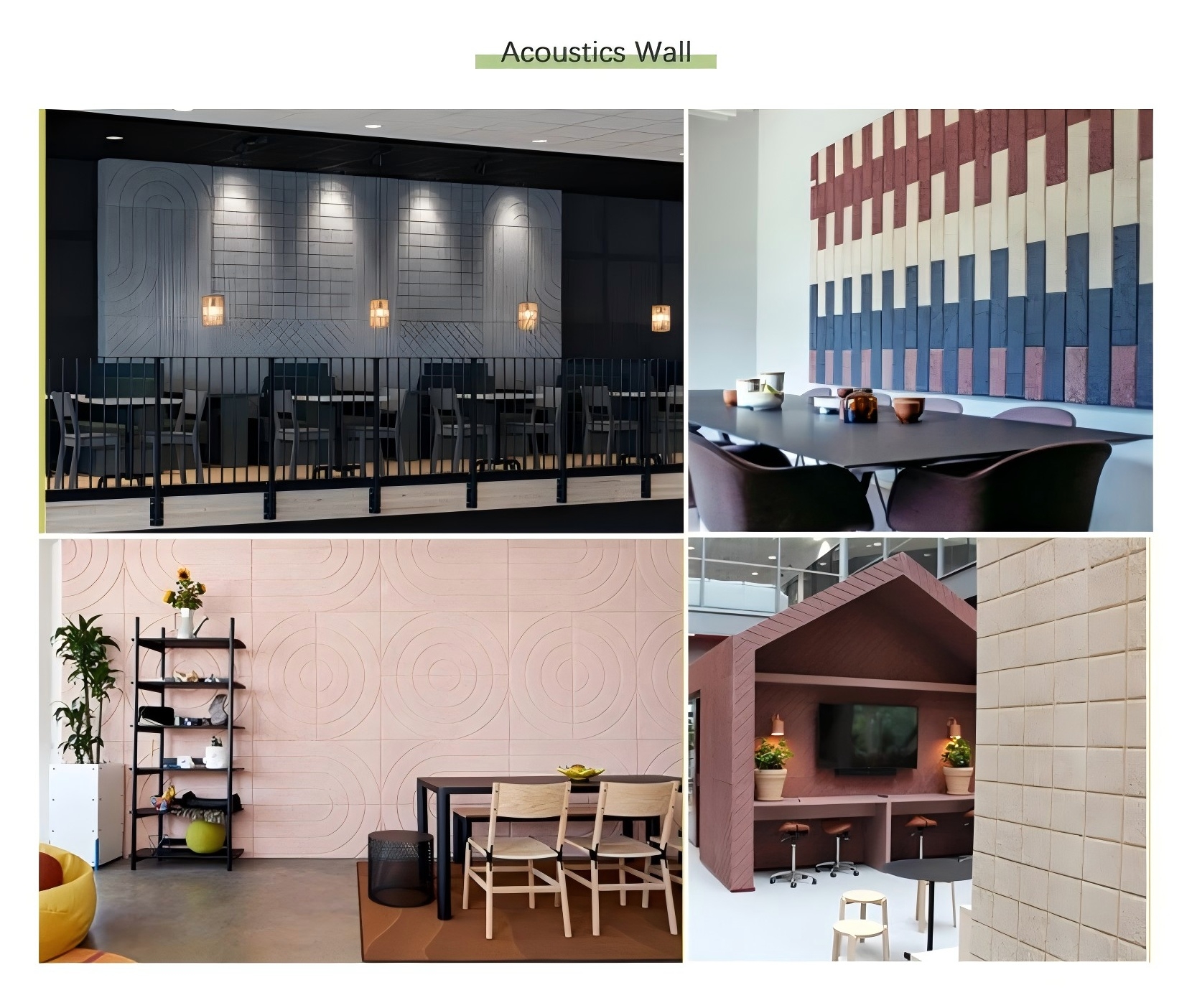

Because the acoustic wood wool panel is made of cement paste and wood silk, so it has good hardness and stiffness. This material is a rigid board with a fairly open structure and has many excellent features. It has the characteristics of sound absorption, heat insulation, moistureproof, fire prevention, long bacteria prevention, pest prevention and dew prevention. acoustic wood wool panel is simple in structure and easy to install, is now widely used in the market sound absorption material.

Specifications

● Basic material: wood fiber and inorganic cement

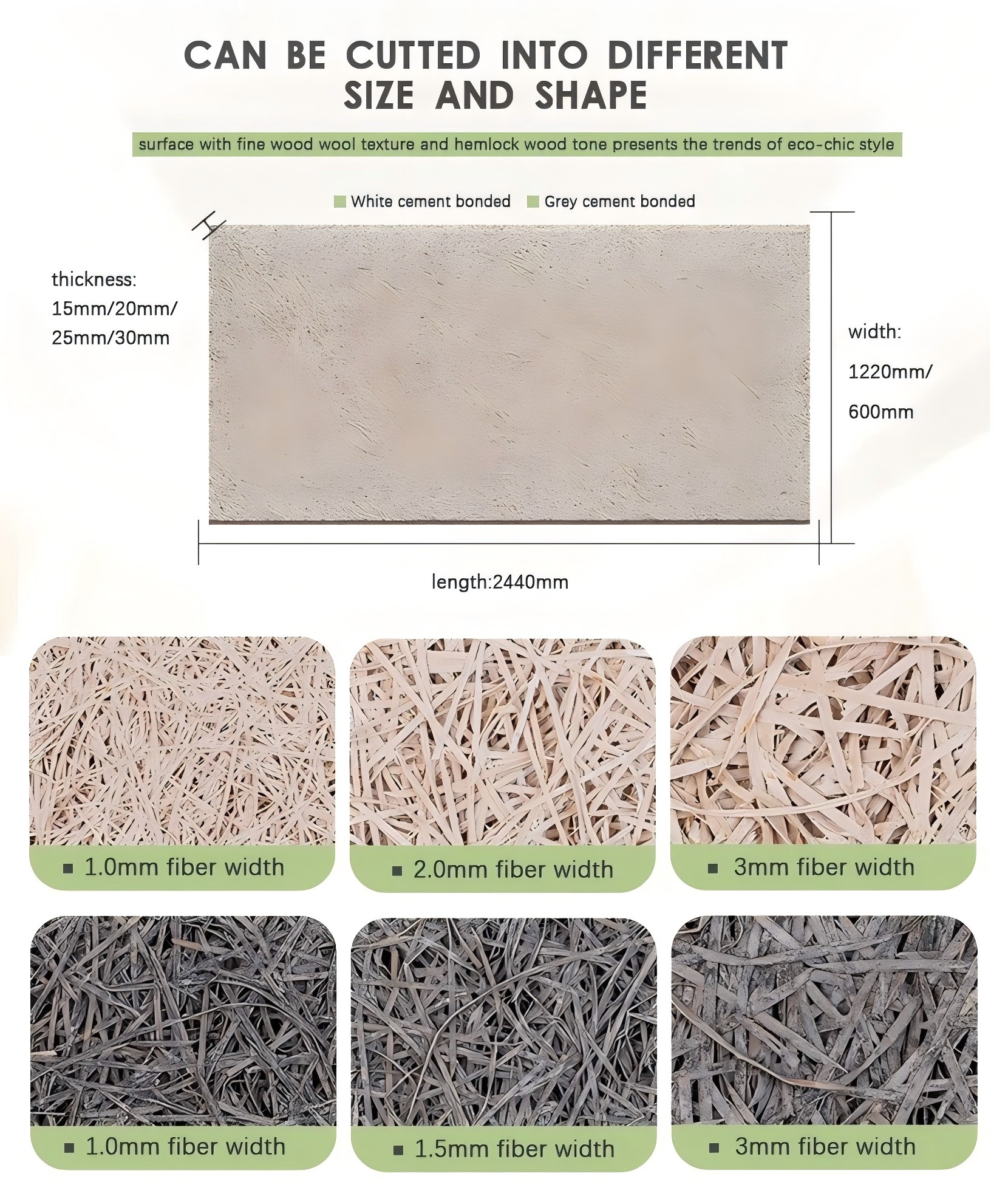

● Standard size: 1220mmx2440mm. 1200mmx600mm, 600mmx600mm,etc

● Standard thickness: 15mm/20mm/25mm

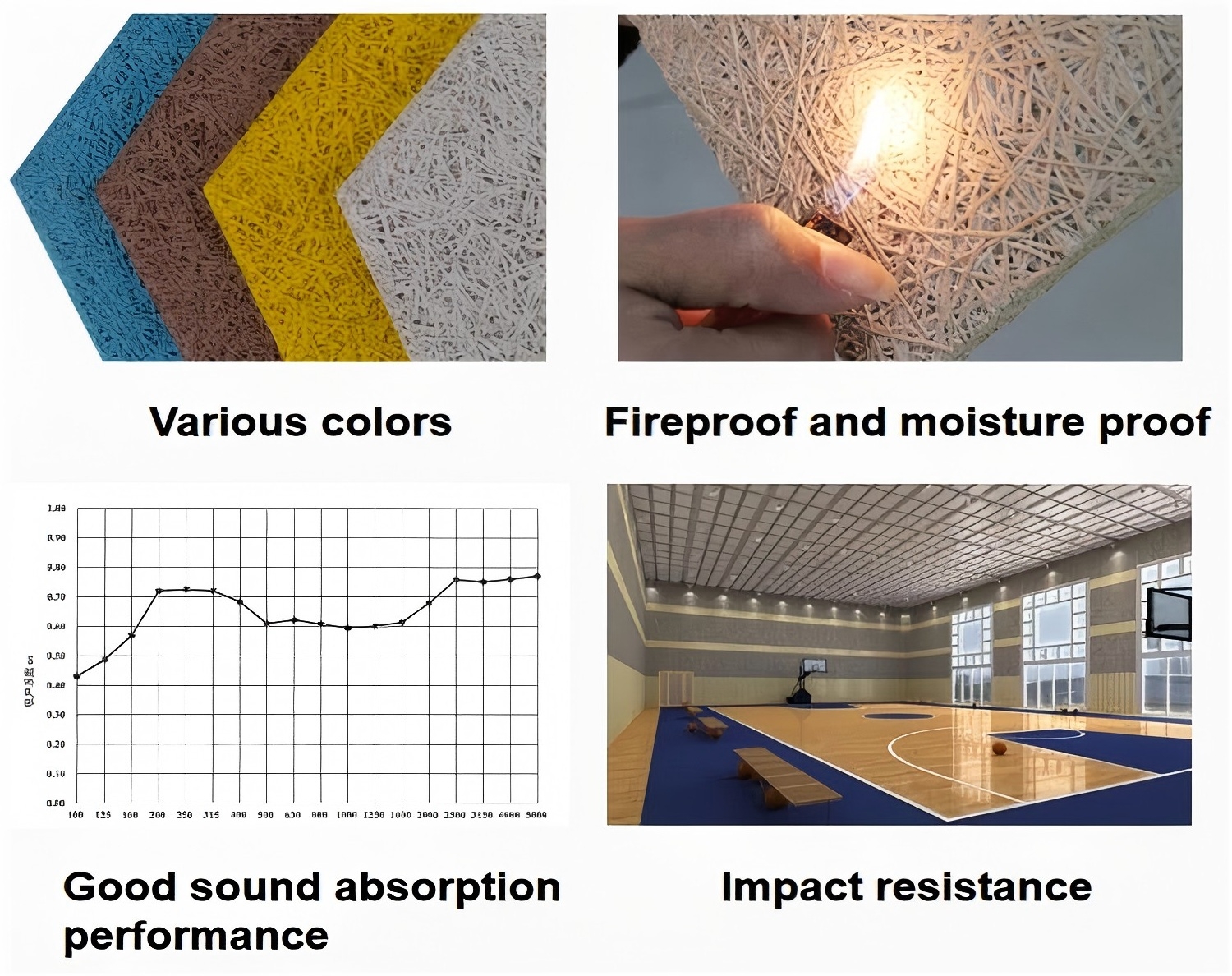

● Color: Original color/ PU painting

● Wool width: 1.0/ 1.5 mm

● Fire retardant: B1

● Density(Kg/m3): 300 ~ 330

● Thickness Expansion (Immersion in water 24hrs) <2%

● Thermal conductivity 0.108 kcal/m x r x ℃

● Thermal conductivity 0.108 kcal/m x r x ℃

Installation Methods

Option 1

Screw the wood wool wall panel on the wall directly.

Option 2

Screw the base wooden batten on the wall, then screw the wood wool acoustic panel on the batten.

Option 3

Fix installation accessories both on the wall and the wood wool acoustic panel, then clip the panel on the wall.